Ball screw JPF, (บอลสกรู JPF, which is the term in Thai) are mechanical tools that are essential to many sectors of the economy, including manufacturing, aircraft, robotics, and automation. They are crucial for processes like CNC machining, 3D printing, and robotics because they transform rotational motion into accurate linear motion.

The following are important details concerning ball screws:

How They Operate

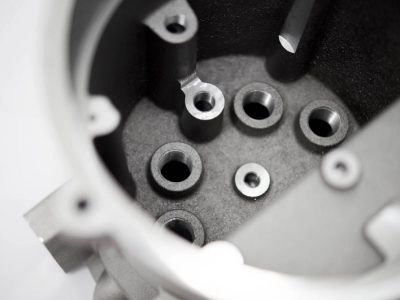

Ball screws are fundamentally made up of a screw (a threaded shaft), a nut (which houses ball bearings), and a number of recirculating ball bearings. The ball bearings slide along the helical groove in the nut as the screw revolves. This action transforms rotational motion into linear motion, enabling exact positional control.

High Performance

Ball screws are known for their remarkable mechanical efficiency. Ball screws employ rolling friction between the balls and the grooves as opposed to standard lead screws, which rely on sliding friction. By doing this, friction is decreased, increasing efficiency and lowering power loss.

Accuracy And Precision

The extraordinary precision and accuracy of ball screws is one of its main benefits. They are perfect for situations where exact positioning is crucial because they can deliver very accurate linear motion with little backlash.

Carrying Capacity For Loads

Ball screws are able to move heavy objects with accuracy and efficiency. They are frequently employed in demanding situations involving strong forces, such as industrial automation and CNC machining.

Backlash

The little play or clearance between the nut and the screw is referred to as backlash. Ball screws are made to have as little backlash as possible, so that there is little movement when the direction of rotation changes. For accuracy to be maintained, this is essential.

Lubrication

Ball screws must be properly lubricated to function smoothly and last a long time. Lubricants lessen wear and friction between the grooves and the balls. Regular checks and replacements for lubricant should be included in maintenance programs.

Setting Up And Aligning

Ball screws must be installed and aligned correctly for best performance. Increased wear, decreased precision, and early failure can all be effects of misalignment.

Maintenance

Ball screws require regular maintenance, which includes lubrication and inspection, to maintain their durability and dependability. Regular inspections for wear or damage are essential to avoid unanticipated failures.

To Conclude

Ball screws are useful and crucial parts in many different sectors because they offer perfect linear motion, a large carrying capacity, and outstanding precision. Ball screws that have been properly developed, installed, and maintained are essential for attaining accurate and efficient mechanical motion in a variety of applications.

Comments