In the realm of modern automotive repair and maintenance, Engine Control Modules (ECMs) are pivotal components that dictate engine performance and efficiency. As vehicles become increasingly sophisticated, the importance of ECMs in managing various engine functions has grown exponentially. This article delves into the significance of ECM Repair Solutions, exploring the reasons for ECM malfunctions, repair methods, and best practices for ensuring optimal vehicle performance and reliability.

Understanding ECM and Its Role

The Engine Control Module (ECM) is the brain of a vehicle’s engine management system. It is responsible for controlling crucial functions such as fuel injection, ignition timing, and emission controls. By continuously monitoring various engine parameters through sensors, the ECM ensures that the engine operates efficiently and meets emissions standards.

The Importance of ECM Repair Solutions

An ECM failure can lead to a host of issues, ranging from reduced engine performance and increased fuel consumption to complete engine failure. Therefore, effective ECM Repair Solutions are essential for diagnosing and resolving problems to restore the engine’s functionality and maintain vehicle reliability.

Common ECM Problems and Their Causes

Understanding common ECM issues is the first step in implementing effective ECM Repair Solutions. Some prevalent problems include:

1. Electrical Failures

Electrical issues, such as short circuits or faulty connections, are among the most common causes of ECM failure. These failures can result from exposure to moisture, vibration, or aging components.

2. Software Corruption

The ECM operates based on complex software algorithms. Corruption or bugs in this software can disrupt the ECM’s ability to manage engine functions accurately. Software issues may arise from improper updates or malware infections.

3. Sensor Failures

The ECM relies on data from various sensors to make real-time adjustments. If a sensor fails or provides inaccurate data, the ECM may make incorrect adjustments, leading to performance issues.

4. Physical Damage

Physical damage to the ECM, such as from accidents or harsh operating conditions, can impair its functionality. Such damage often requires immediate attention to prevent further engine issues.

ECM Repair Solutions: Methods and Best Practices

When faced with ECM issues, a comprehensive approach to repair is crucial. The following ECM Repair Solutions provide a structured pathway to diagnosing and addressing problems:

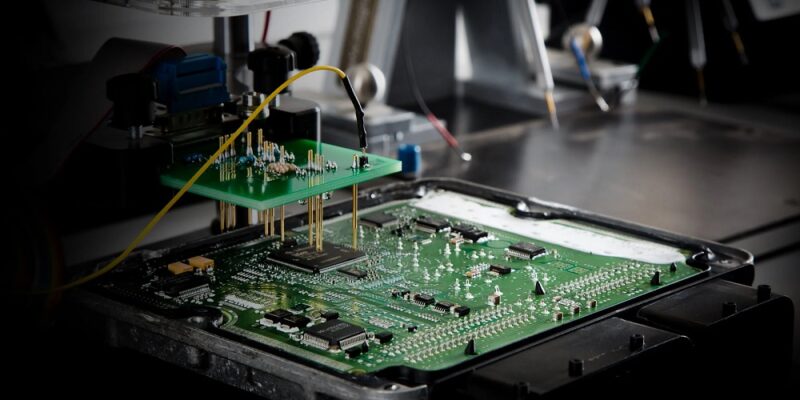

1. Diagnostic Testing

Before initiating repairs, thorough diagnostic testing is essential. Advanced diagnostic tools and scanners are used to read error codes and assess the ECM’s functionality. This process helps identify the specific problem areas, whether they are electrical, software-related, or sensor-based.

2. Software Reprogramming and Updates

If software corruption is detected, reprogramming or updating the ECM software may resolve the issue. This process involves installing the latest software version from the vehicle manufacturer to correct bugs and enhance performance.

3. Component Replacement

In cases of physical damage or failed components, replacing the damaged parts or the entire ECM may be necessary. High-quality replacement parts or remanufactured ECM units should be used to ensure compatibility and reliability.

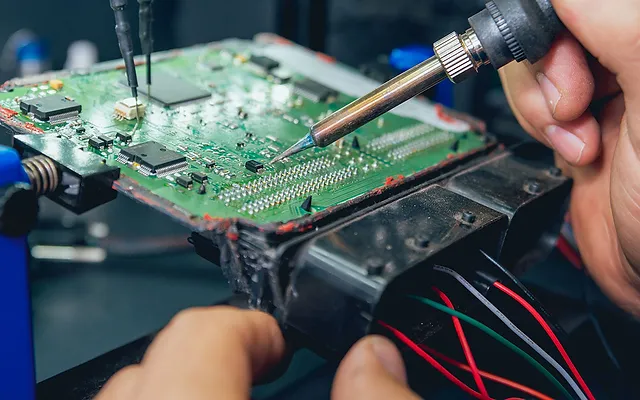

4. Electrical Repair and Testing

Repairing electrical issues involves inspecting wiring and connectors for damage or corrosion. Electrical repairs may include soldering connections, replacing damaged wires, or securing loose connections. Testing the repaired system ensures that the issue has been resolved.

5. Sensor Calibration

For sensor-related problems, recalibrating or replacing faulty sensors is crucial. Accurate sensor data is vital for the ECM to make precise adjustments, ensuring optimal engine performance.

Preventive Measures and Maintenance

To minimize the risk of ECM issues and extend the lifespan of the component, regular maintenance and preventive measures are recommended:

1. Routine Inspections

Regular vehicle inspections can help detect potential ECM problems early. Mechanics should check for signs of electrical issues, software updates, and sensor functionality during routine maintenance.

2. Protective Measures

Protecting the ECM from moisture, vibration, and extreme temperatures can prevent damage. Using protective covers and ensuring proper installation can enhance the ECM’s durability.

3. Software Updates

Keeping the ECM software up-to-date ensures that it operates with the latest enhancements and fixes. Regular updates from the vehicle manufacturer can prevent software-related issues.

4. Professional Repairs

Engaging qualified technicians for ECM repairs ensures that the work is performed accurately and with the appropriate tools and parts. Professional repair services provide a guarantee of quality and reliability.

Conclusion

ECM Repair Solutions play a crucial role in maintaining the performance and reliability of modern vehicles. By understanding common ECM problems, implementing effective repair methods, and adhering to preventive measures, vehicle owners can ensure that their engines run smoothly and efficiently. Investing in professional ECM repair services not only resolves current issues but also helps prevent future problems, contributing to the overall longevity and functionality of the vehicle.

In a landscape of increasingly complex automotive technology, having access to reliable ECM Repair Solutions is essential for optimal vehicle operation and performance.

Comments