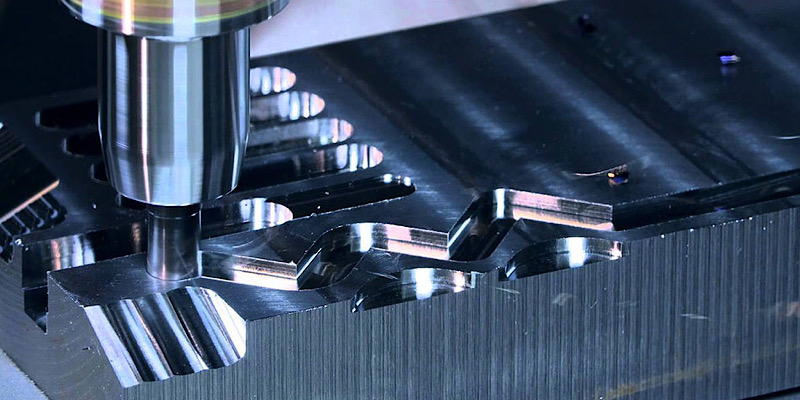

Computer numerical control (CNC) machines to produce engineering parts using raw materials. One of the most common kinds of CNC machining is CNC milling meant to eliminate material from a solid block to produce parts. As with other drilling machines, milling machines are meant to cut and drill materials. But, they can cut in various angles and move along varying axes. Just like the majority of CNC machining processes, milling depends on computerised controls for operating the stock material cutter and shaper. For businesses, CNC milling offers solid benefits.

Reduced Production Times

The use of a CNC milling machine eliminates months of planning, designing, and manufacturing prototypes. Also, there is no need to spend time on the inspection process. What’s involved is inspecting the initial part the milling machine produces. When approved, the machine can produce a 100% replica of this part.

In addition, computer controls operate the machines, eliminating errors during the process. The human operator will just feed the machine’s controller with digital computer orders and instructions. Then, the settings will work based on the instructions provided.

Minimise Labour Requirements

With CNC milling, only an operator or supervisor is required to make sure the process is performed smoothly. As a result, you can reduce labour costs. And when you hire LOCUS Precision milling services, you enjoy the savings through their affordable rates.

Improved Efficiency

As CNC milling machines are designed to operate non-stop, they can produce the parts you need continuously until your orders are filled. The only time these machines have to be switched off is for maintenance and repair purposes. And since these machines may allow idea simulation, building or using a prototype may not be necessary. Once they are programmed, they can produce replicas that have the same precision each time.

Product Accuracy and Precision

A CNC machine includes advanced features and software that ensure every milled piece is produced accurately. Also, the milling process guarantees a high degree of repeatability. The majority of the software programs used on these machines are easy to understand, make it possible for operators to follow the manufacturer’s manual when they operate the machine for the first time.

Production Versatility

CNC machining service providers deal with a lot of materials regularly. CNC milling machines let them shape and cut materials while maintaining both efficiency and quality. Because these machines can work with different types of materials, operators can multitask and produce various parts in one go.

Comments